Why Customers Choose Us

We deliver exceptional value through quality, efficiency, and expertise. Discover the advantages of partnering with us.

High Quality Parts

Our components undergo rigorous testing and meet international standards, ensuring reliability and longevity in even the most demanding applications.

- ISO 9001 Certified

- 100% Quality Inspection

- Premium Material Selection

Fast Lead Time

We understand that time is critical for your operations. Our optimized supply chain allows us to deliver 95% of orders within 48 hours.

- 48-Hour Standard Delivery

- Express 24-Hour Option

- Real-Time Order Tracking

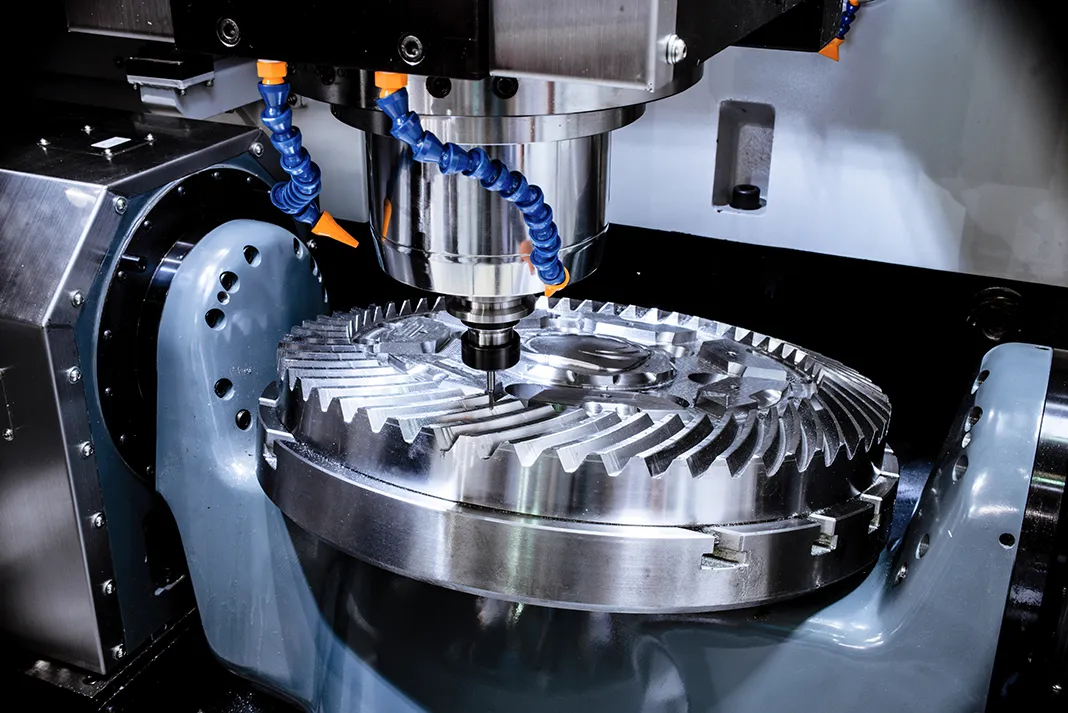

Engineering Support

Our team of experienced engineers provides expert guidance from selection to implementation, ensuring optimal performance for your specific needs.

- Expert Technical Consultation

- Custom Solution Development

- Dedicated Support Specialists

What Our Clients Say

"The quality of components has significantly reduced our maintenance costs. Their engineering team helped us select the perfect solutions for our unique production environment."

— Sarah Johnson, Plant Manager

"When our production line needed critical parts urgently, they delivered within 24 hours, saving us from costly downtime. Their responsive support makes them an invaluable partner."

— Michael Chen, Operations Director

Ready to Experience the Difference?

Join hundreds of satisfied customers who trust us for quality, speed, and expertise.

Contact Us Start Your New Instant Quote