Manufacturing on Demand for the Medical Industry

Trusted by Over 56% of the Fortune 600 Medical Products and Equipment Companies

Trusted by Over 56% of the Fortune 600 Medical Products and Equipment Companies

We deliver exceptional value through quality, efficiency, and expertise. Discover the advantages of partnering with us.

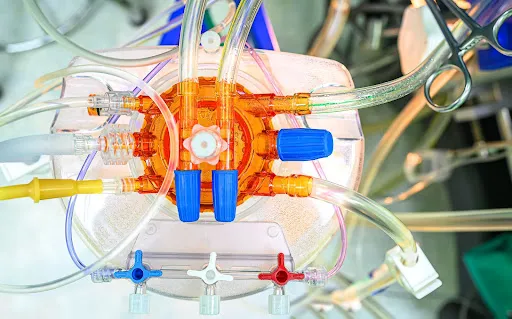

Our components undergo rigorous testing and meet international standards, ensuring reliability and longevity in even the most demanding applications.

We understand that time is critical for your operations. Our optimized supply chain allows us to deliver 95% of orders within 48 hours.

Our team of experienced engineers provides expert guidance from selection to implementation, ensuring optimal performance for your specific needs.

"The quality of components has significantly reduced our maintenance costs. Their engineering team helped us select the perfect solutions for our unique production environment."

— Sarah Johnson, Plant Manager

"When our production line needed critical parts urgently, they delivered within 24 hours, saving us from costly downtime. Their responsive support makes them an invaluable partner."

— Michael Chen, Operations Director

Join hundreds of satisfied customers who trust us for quality, speed, and expertise.

Contact Us Start Your New Instant QuoteGet high-quality prototypes for early-stage product development. Test your designs, make important material and design iterations, and get prototypes ready for testing. At this stage, we will help you create prototypes according to your product’s requirements and design files. Depending on your needs, we will use low-cost materials and processes to develop parts similar to the final product. k

Iterate easily and quickly on precise functional prototypes to ensure all performance requirements are met. Our functional prototypes help you identify every design risk and easily mitigate these risks. This may require several iterations to ensure the prototypes meet all functional requirements and performance metrics.

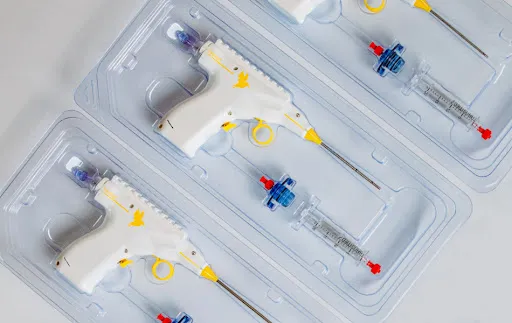

Effectively validate part functionality, performance, and appearance with a wide range of material and surface finishing options. This stage of production helps you analyze the final feel and look of the Medical and Dental component. FlagShip has a wide range of mechanical designs, materials, and finishes that will meet your unique demands.

Prepare your design for full-scale production with production-grade manufacturing capabilities and advanced quality control. Gain control and get feedback on your design from the DVT stage to ensure you achieve production goals. Make final changes to your model to ensure more effective manufacturing.

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products. We take charge of your parts’ production with our engineering expertise and advanced manufacturing process. Our professional technicians ensure your production yield and quality remain high while lowering costs and lead times.

Free shipping available for domestic CNC orders