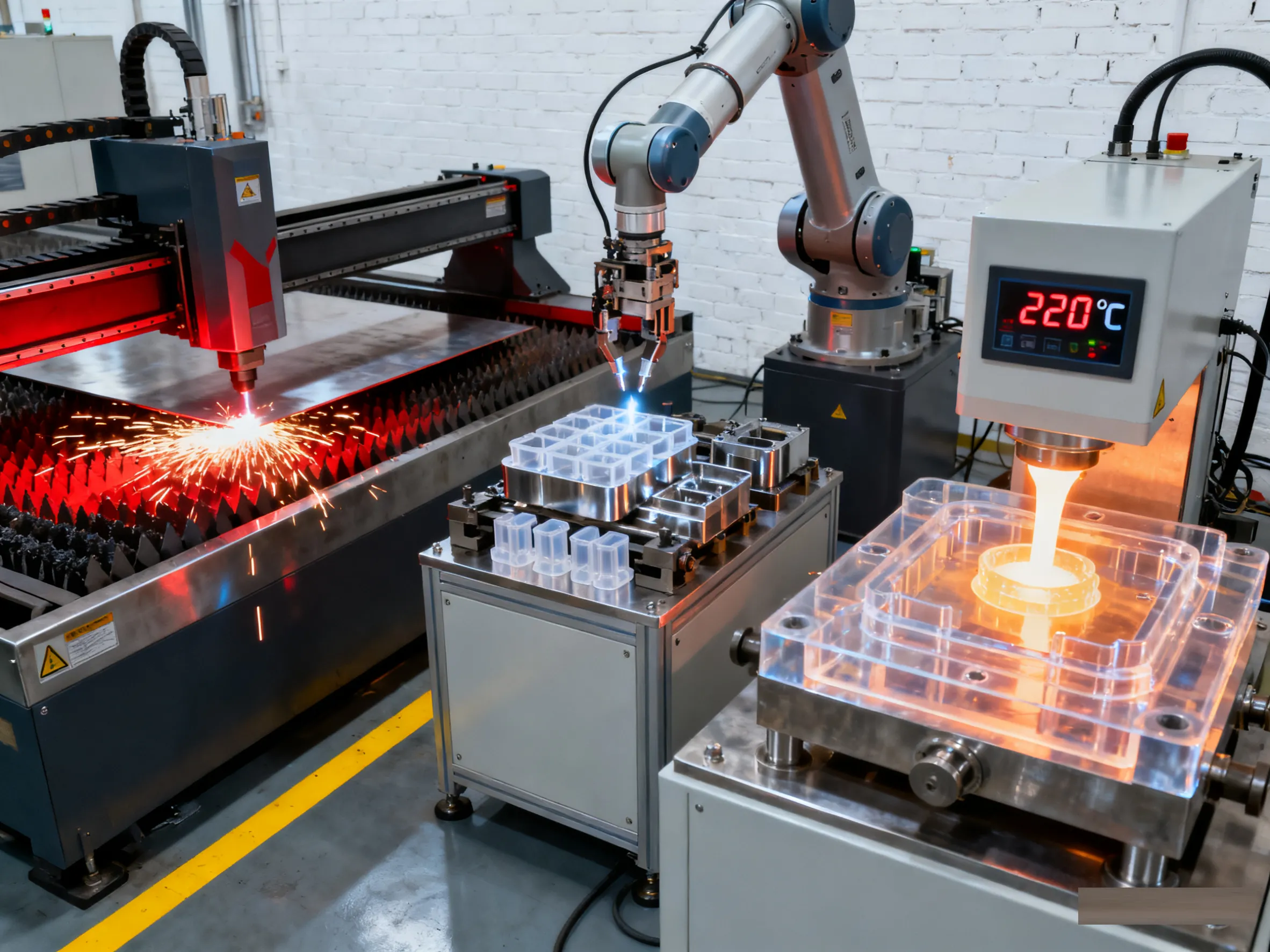

Acetal (Delrin) CNC Machining

Acetal is a high-strength thermoplastic also known by its brand names, Delrin®, Tecaform® and Sustarin®. It has exceptional mechanical properties and temperature resistance when compared to other, more common plastics. It is easy to machine and has excellent dimensional stability. This combination of properties makes CNC machining in Delrin perfect for high-precision mechanical components such as gears and bearings. Delrin parts can be found in consumer electronics such as printers and televisions.