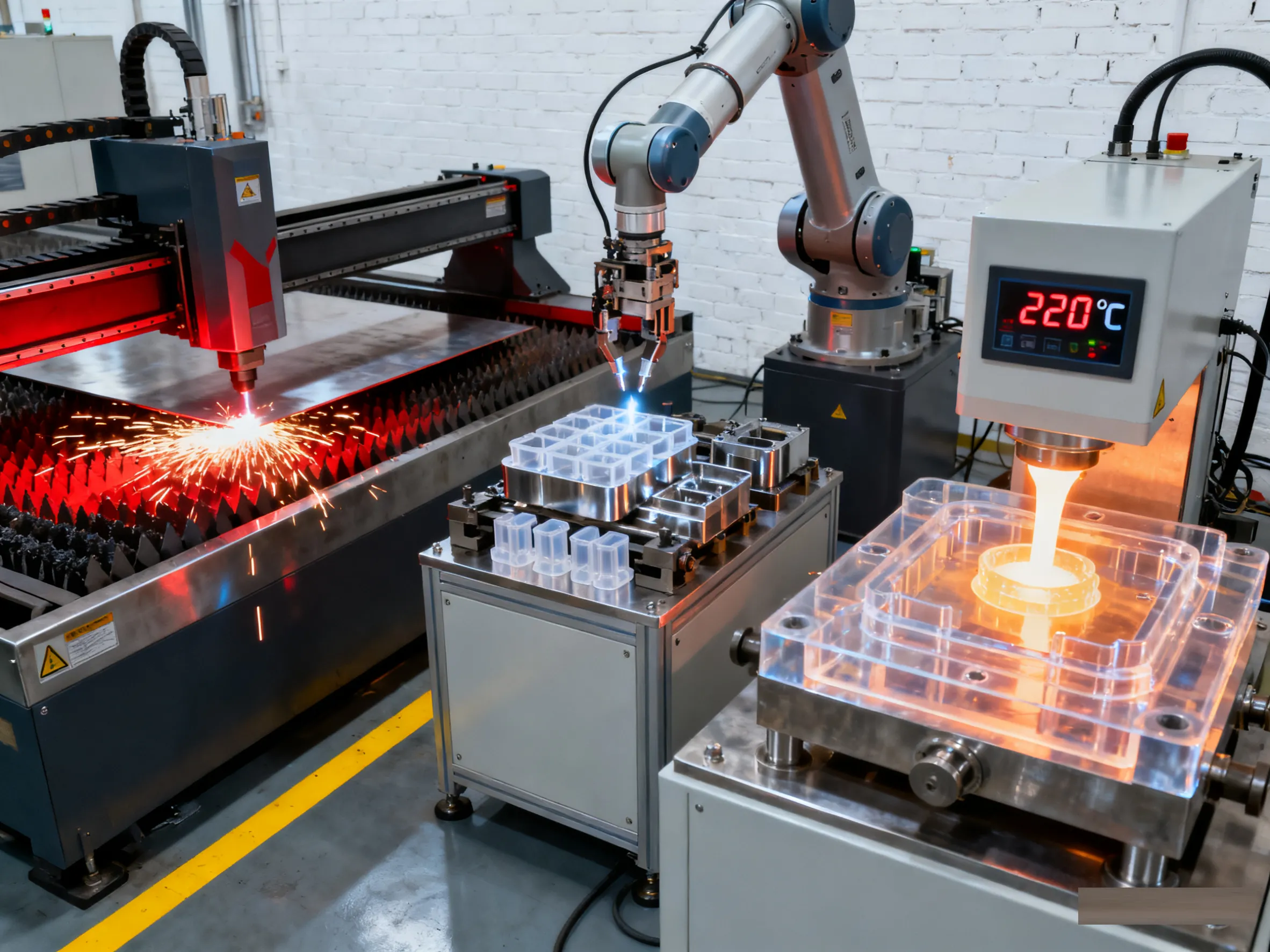

HDPE CNC Machining

High-Density Polyethylene or HDPE is an engineering plastic that is employed extensively in the packaging industry. CNC machining in HDPE can also be used to create components for the construction, electrical, and automotive industries, among others. HDPE has an excellent strength-to-weight ratio, as well as good chemical and moisture resistance.