Teflon (PTFE) CNC Machining Service

Teflon (PTFE) or polyetheretherketone is an advanced engineering plastic with a long list of beneficial properties. These include resilience at high temperatures, abrasion resistance, biocompatibility, resistance to ultra-high vacuum, exceptional chemical resistance, and suitability for CNC machining.

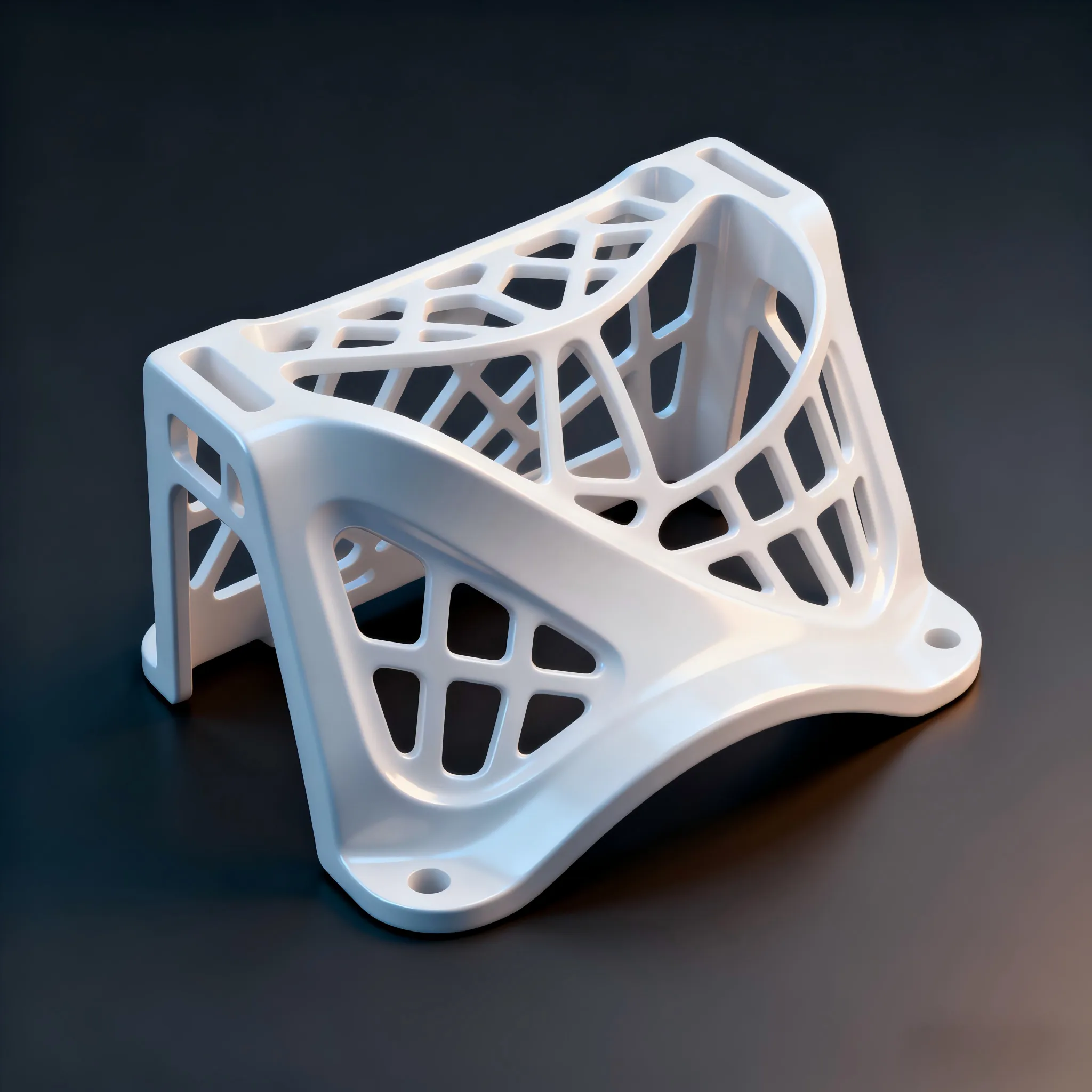

Teflon (PTFE) is a semi-crystalline thermoplastic that can continuously operate at temperatures up to 260°C and is highly chemical resistant. It must be noted, however, that some acids like sulphuric acid will dissolve the material. CNC machining in Teflon (PTFE) is a common way to manufacture parts for use in extreme environments that require mechanical strength, chemical stability, and/or high-temperature resistance. Applications include components for the medical, aerospace, and automotive industries.