Finishes

Only a limited range of surface finishes work on plastics. This is especially the case when CNC machining in polycarbonate because the material tends to scratch easily. Some possible finishes are listed below:

Vapor polishing:

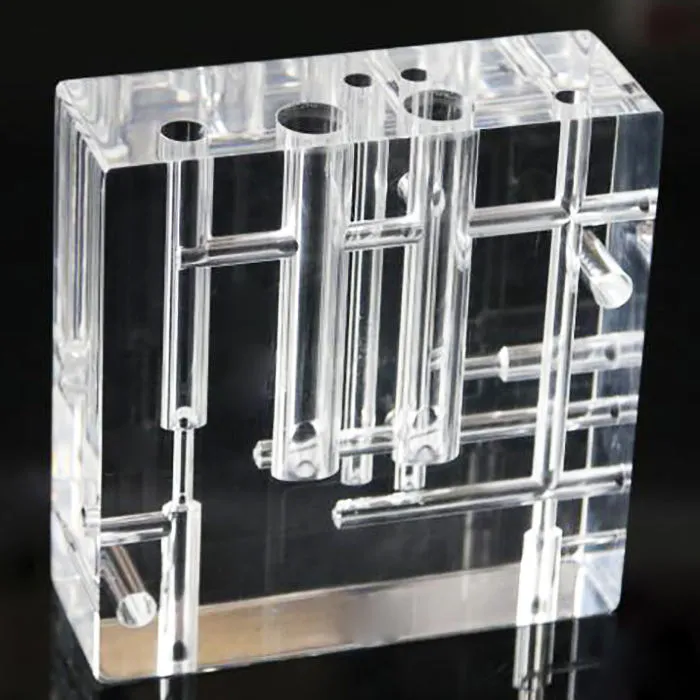

CNC-machined polycarbonate often comes out with tool marks on the surface. This is not ideal for applications that require optically clear components. Polishing, in general, is the process of removing tool marks or blemishes, and one of the more effective methods when it comes to polycarbonate is vapor polishing. This works by exposing the surface to a solvent that reacts and causes the surface layer to melt and flow. The process evens out the surface and fills in any tool marks.

Scratch-resistant coating::

One disadvantage of polycarbonate is its propensity to scratch easily. Some coatings on the market help maintain the optical clarity of polycarbonate while improving its scratch resistance.