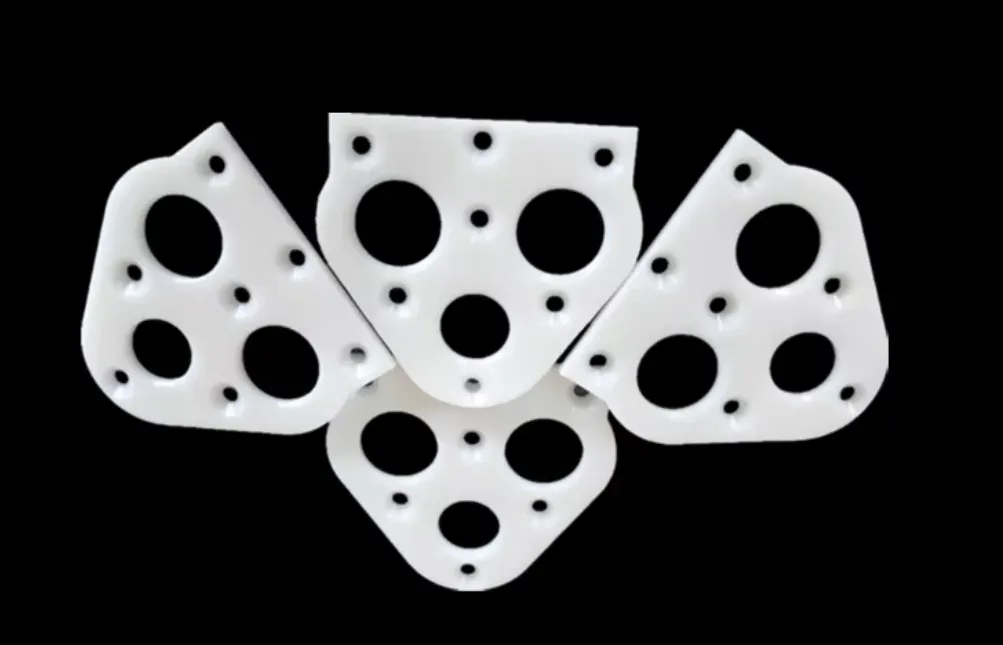

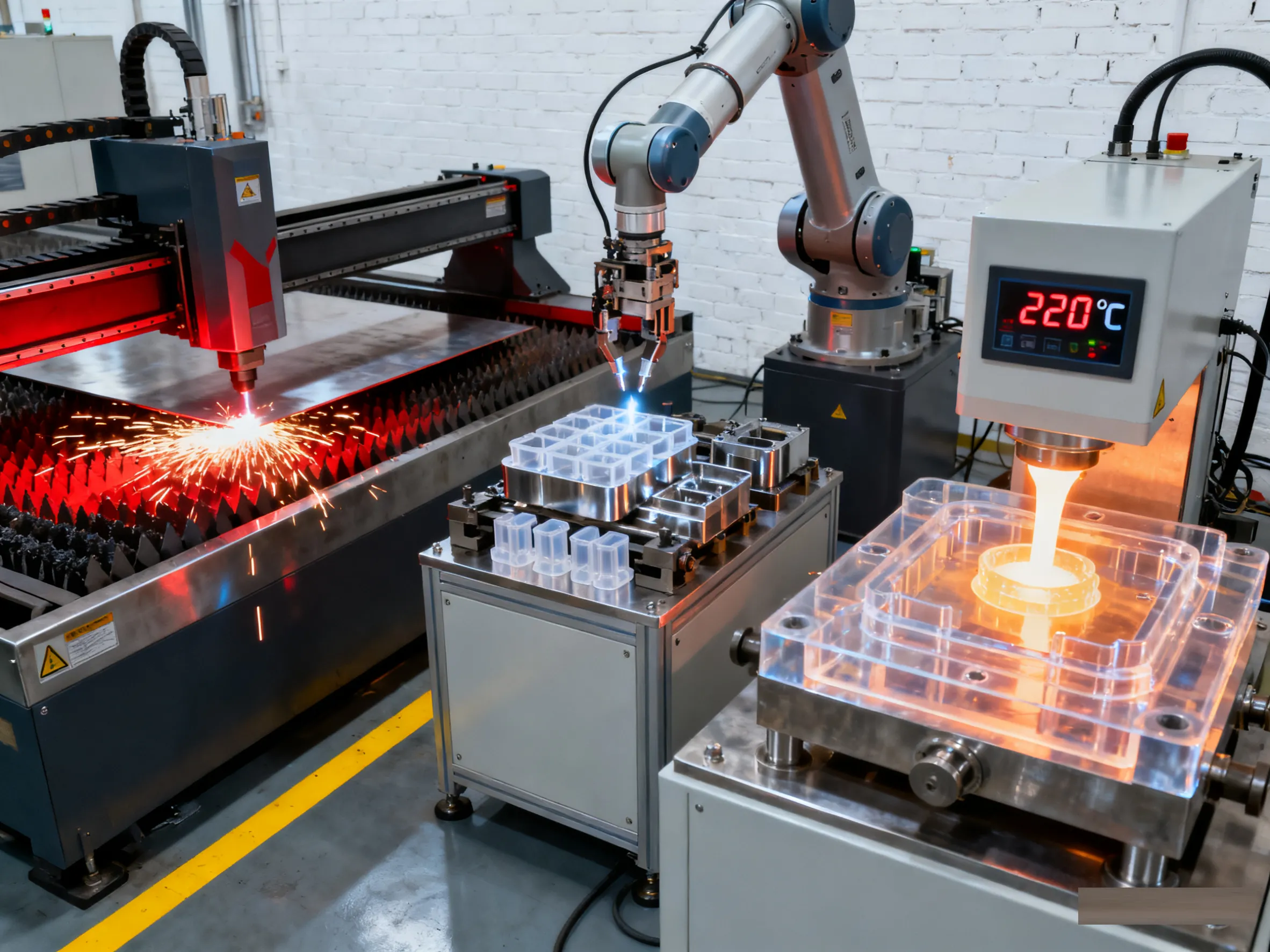

Polypropylene (PP) CNC Machining

Get instant quotes on custom polypropylene machined parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. ITAR registered.