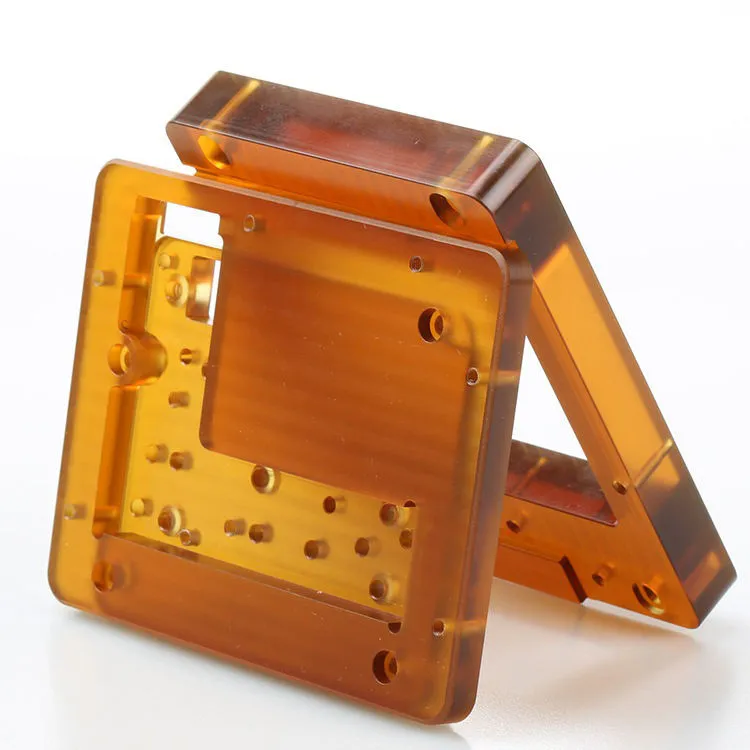

ULTEM CNC Machining Service

Get instant quotes on custom CNC machined ULTEM parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.